We offer different variants of tabletops for stands top cover according to your choice:

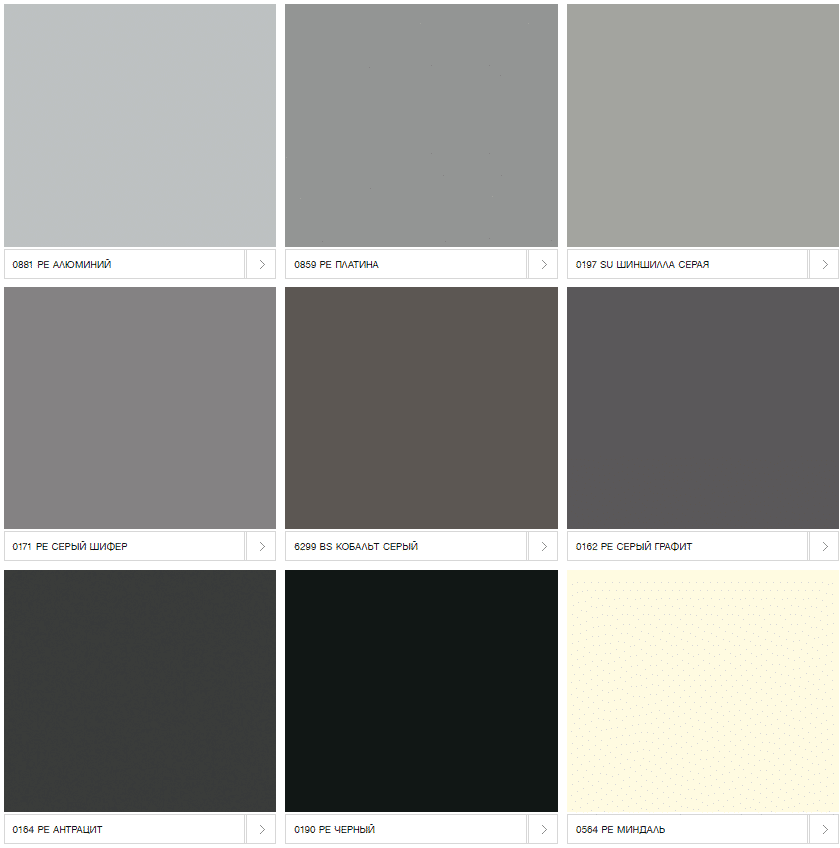

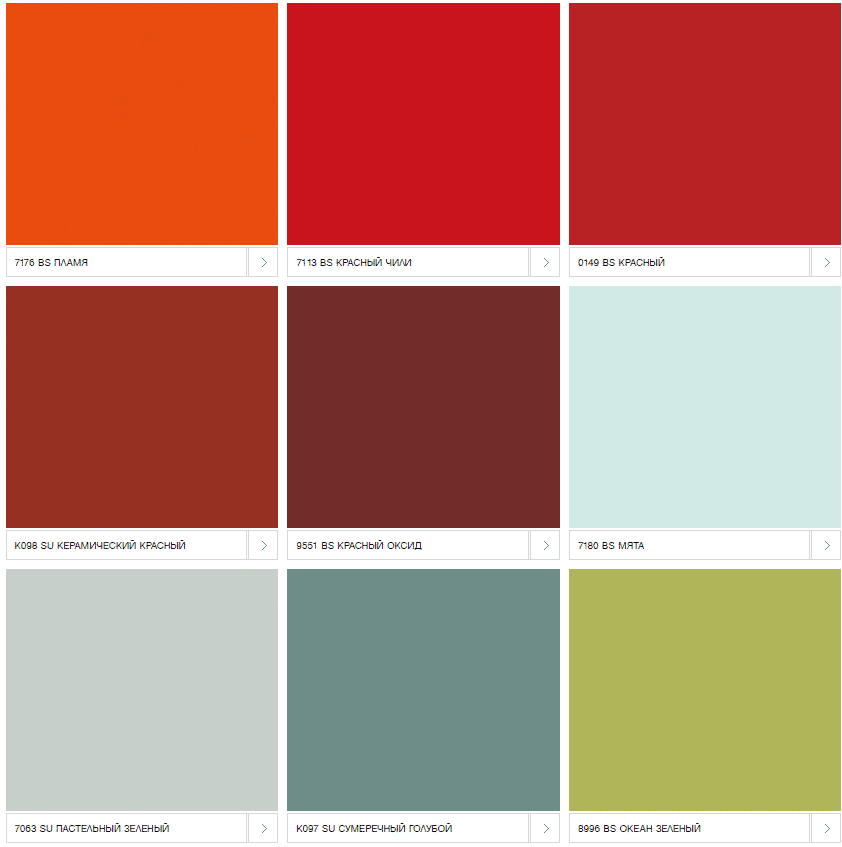

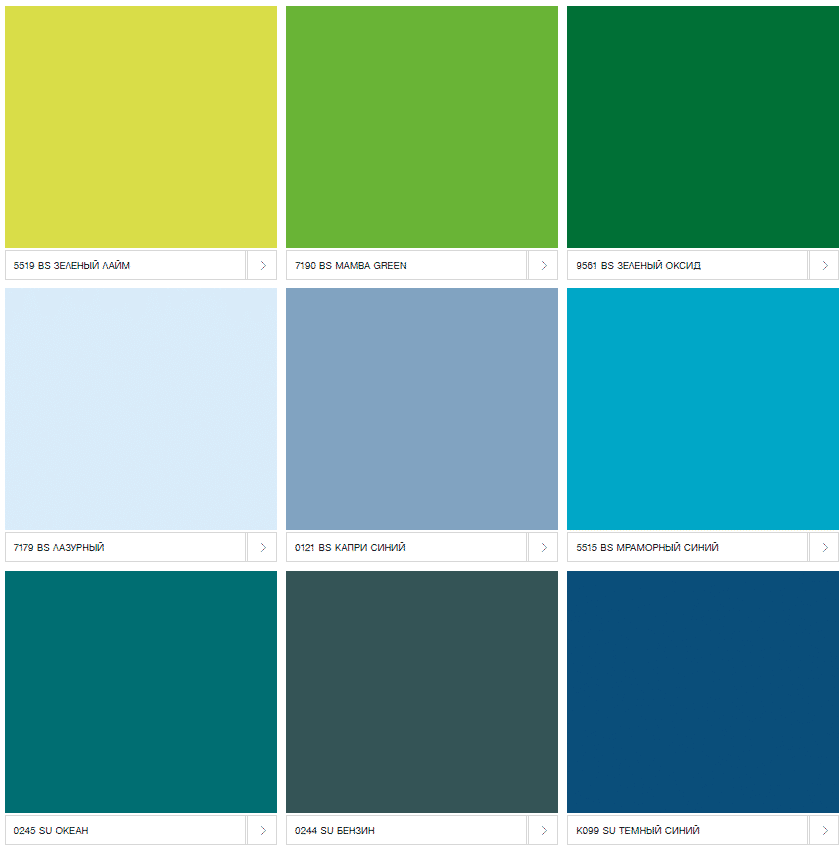

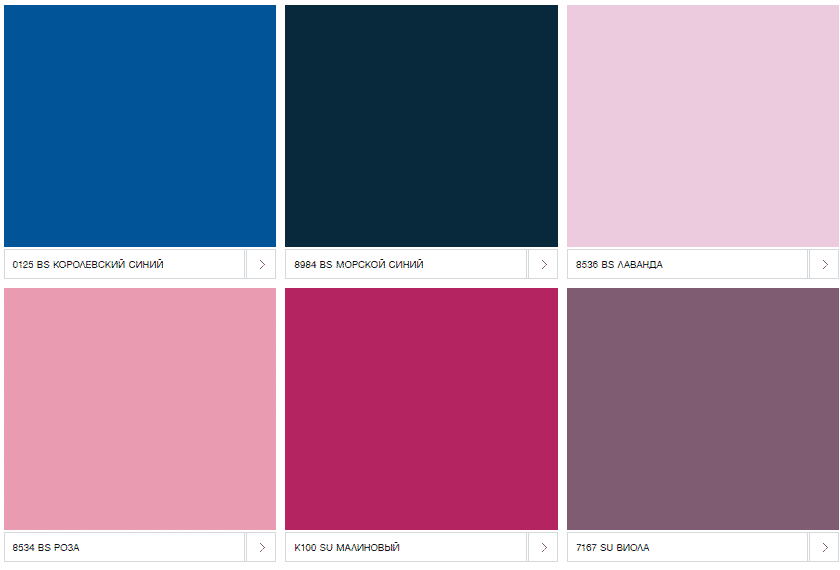

«STANDARD LINE» tabletop from composite particle board -(postforming)- is supplied as part of package and is delivered free, standard white colour, alternate colours are at the foot of the page. Maximum length is 3 metres, no limitation when jointed.

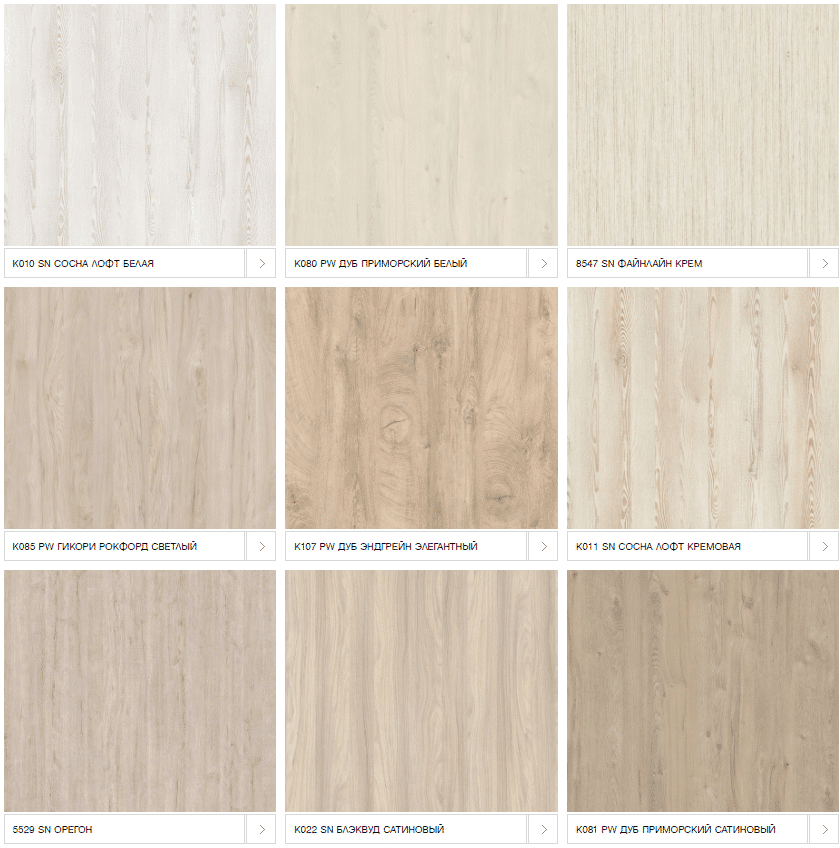

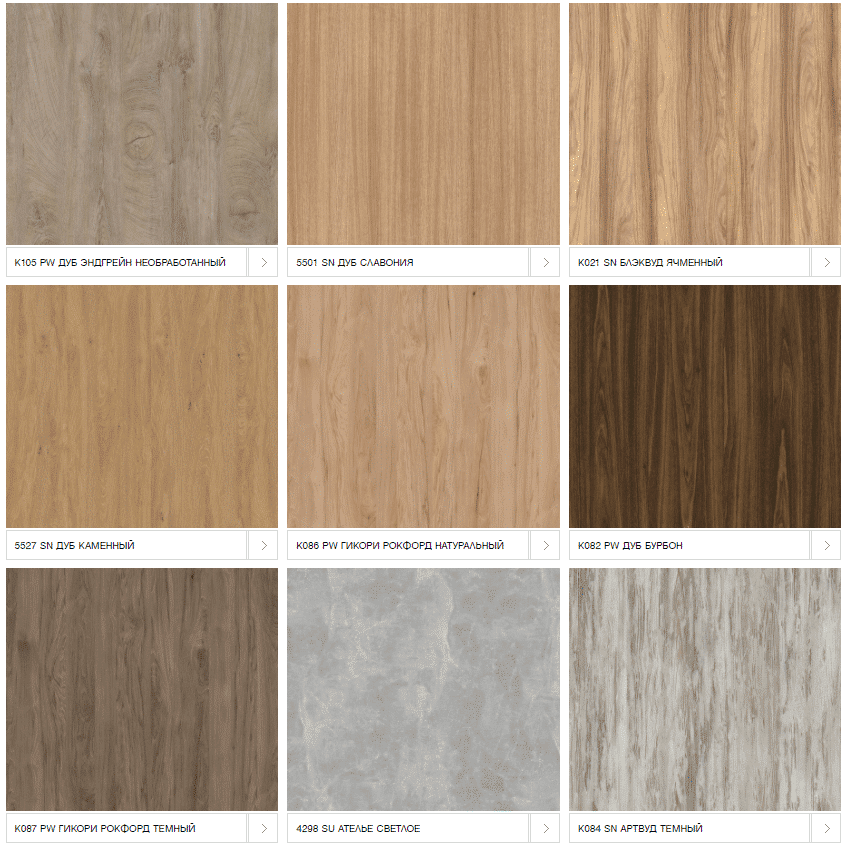

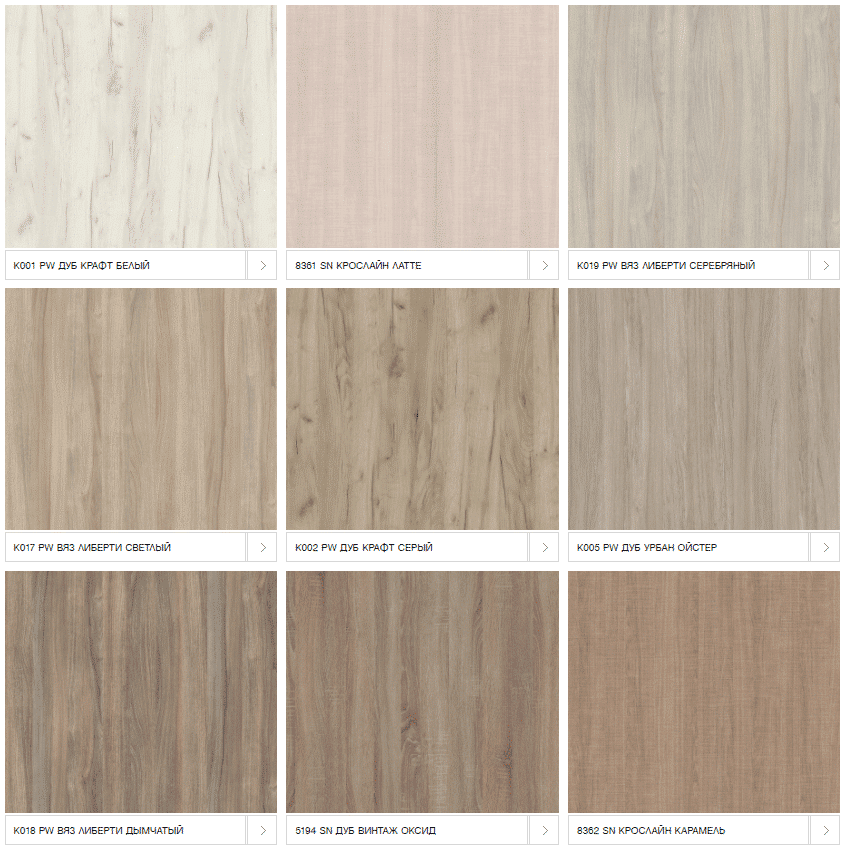

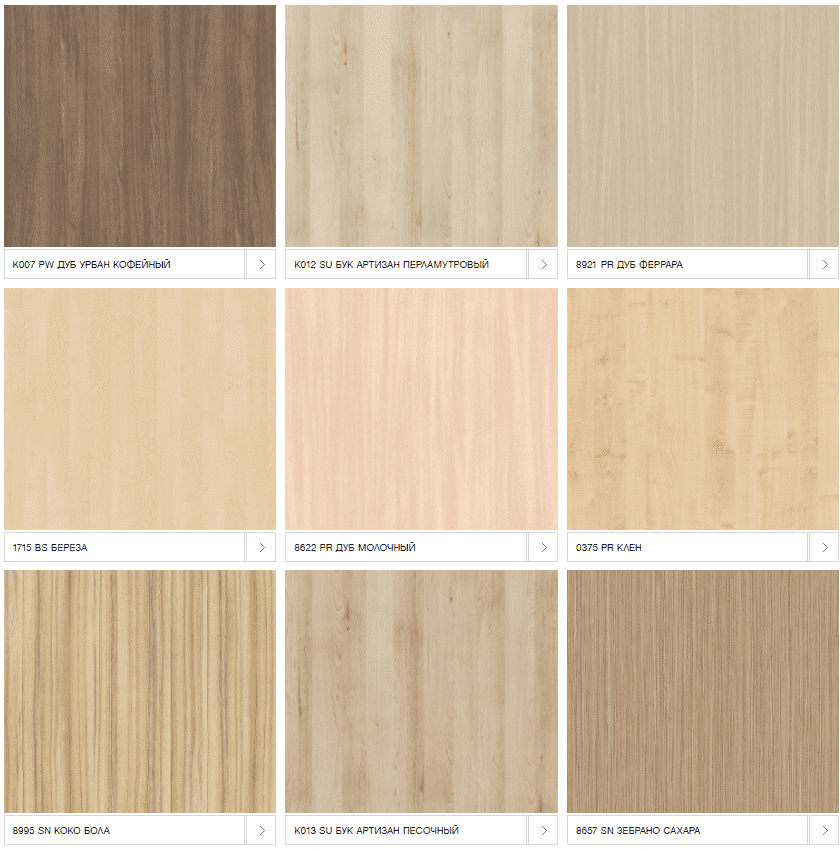

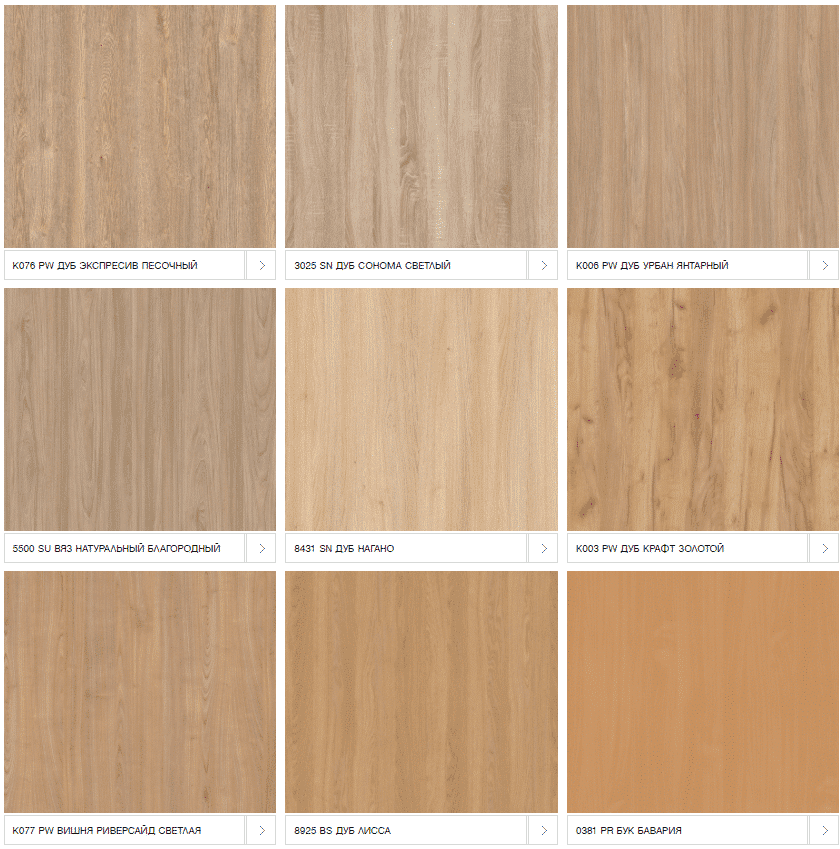

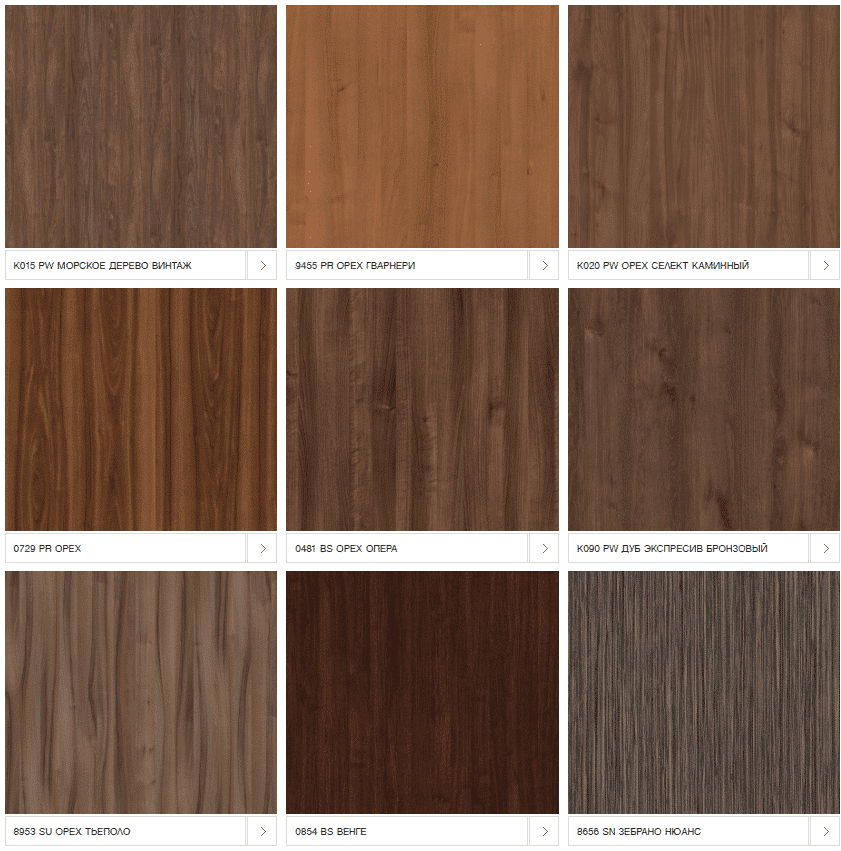

Postforming colouring (40% extra pay for colours others than white).

Note: You should bear in mind that decoration colours on Your display might slightly differ from the original.

«STANDARD LINE» tabletop from composite particle board (postforming)

Surface coating thermoresistance is higher than normal – resists temperature up to 300 С.

Plastic is highly shock-proof and resistant to any mechanical impact.

Seal layer at the joint of plastic and counter weight totally excludes penetration of water.

Composite particle board is 28 mm thick and conforms to Е1 class of hygiene in the content and emission of formaldehyde (according to «Perforator» method the content of formaldehyde for the boards up to 18 mm thick is 9-18 mg/100g; over 18 mm — 4-6 mg/100 g).

The board face surface is laminated with high pressure laminate (HPL).

All plastics and applied glues conform to ISO 9001 quality standard, they are free of asbestus, plumbum and heavy metals. Environmentally clean materials are used for their production. The board backside is covered witha layer of antistress material, which is moisture-protective at the same time.

There are more than 100 colours available.

Postforming board is made from composite particle board of Е1 class of hygiene, 28 and 38 mm thick. The surface is covered with postforming plastic, joint at the curvature is glued to avoid moisterizing and delamination. Standard size of postforming board is 3050х600х28. Surface specification: GR – orange peel; SD – tree structure; P- gloss; PP – semigloss; MG – matted smooth.

Note: You should bear in mind that decoration colours on Your display might slightly differ from the original.

1. Belgian-made «INOX LINE» tabletops from mirror stainless steel (Х5 CrNi 18-10) – at the price 60, – per one module covering. Maximum structure spacing is 2 metres, no limits when jointed.

Stainless steel tabletops are used to secure the highest purity, aesthetics, high temperature and strength resistance in order to avoid corossion. Stainless steel acquires its properties mainly due to the chrome content. When a common tabletop does not fit, it is effectively replaced by a stainless steel tabletop.

2. German-made «GLASS LINE» tabletops are from glass – at the price 100,- per one module covering. Maximum structure spacing is 3 metres, no limits when jointed.

3. «STONE LINE» tabletop is from natural stone (natural granite or marble) – at the price 100 per one module covering. Maximum structure spacing is 1,5 metres, no limits when jointed.

Natural stone combines beauty and eternity. The following hard-rock materials are used for tabletop production: granite (deep-seated rock, consisting from quartz (20-40%), orthoclase (40–70%) and mica (5–20%, as well as other minerals, such as feldspar, microcline, anortosite, etc.) Granite colour is determined by orthoclase colour and it can be grey, bluish-grey, dark red. Granite has a granular-crystalline structure). This rock was formed millions of years ago from magma, slowly growing cool deep in the earth. Granite is extremely hard, waterproof and soiling resistant. Or marble, they are both perfectly fit for medicine.

Tables for food processing

Tables for food processing